Chain vs ERO Joint® belts

Chain vs Timing Belt vs ERO Joint® timing belt

Which power transmission system is the best? Chain, timing belt, or mechanical assembly ERO Joint® timing belt?

Industry use these three systems:

Chain: more flexible (easier to assemble, available in every length)

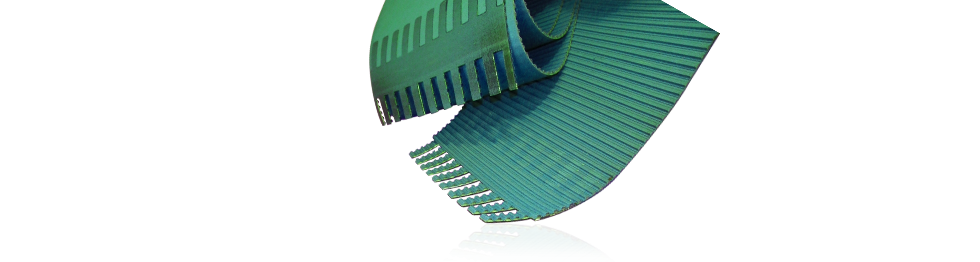

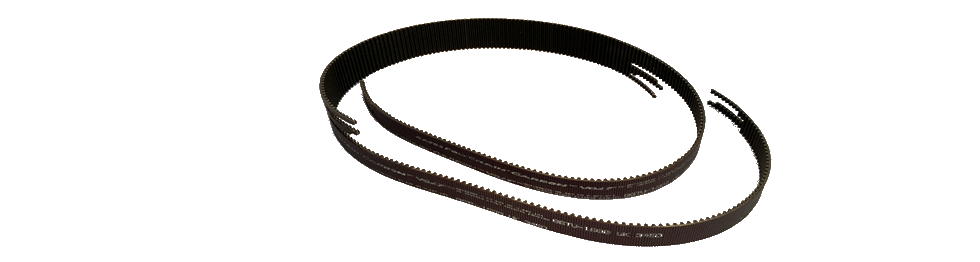

Belt: more powerful (resist to higher rpm), more clean (no lubrication),

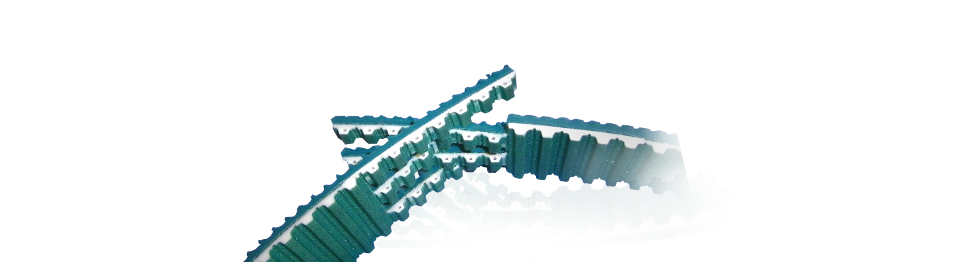

ERO Joint® belt: advantages of belts and add the assembly flexibility of the chain (ERO Joint® belts are produced open, and closed on the machine like a chain).

Watch the video of a bicycle with a belt drive system

"Belts Are The BEST Bicycle Drivetrain Available"

The match Chain vs Belt vs ERO Joint®

Easiness of assembly – Winner: Both Chain and ERO Joint® belts

Belts are closed, so it is easier to assemble an open chain and close it in the machine instead a closed belt.

ERO Joint® belt are open, and closed on the machine. So it is so easy to assemble an ERO Joint® belt than a chain.

Reparability – Winner: Chain

A chain can be repaired by using a replacement link. The belt has to be entirely replaced.

Efficiency – Winner: Belt

Belts weight is lower than chain. The efficiency is better.

Durability – Winner: Belt

Belts usually last at least twice as long as chain. ERO Joint® belt can last as long as closed belts depending on conditions.

Maintenance required – Winner : Both Belt and ERO Joint® belts

Belt requires no lubrication and generally no tension adjustment.

Cost – Winner depends on application

Weight – Winner : Both Belt and ERO Joint® belts

Noise – Winner : Both Belt and ERO Joint® belts

Belts a more quiet than chains. ERO Joint® don’t generate additional noise on the belt.

Cleanliness – Winner : Both Belt and ERO Joint® belts

Belts don’t need lubrication. Chain needs lubrication and dust can be fixed by lubrication but generating dirt.

Dimension availability – Winner : Chain and ERO Joint® belts

It is possible to make every length in chains by adding links. ERO Joint® belts can be made in every length and width. Closed timing belts are made only at certain standard length.

Temperature resistance – Winner : Chain

General temperature range of belts is -30 to +80°C. Temperature range of chains is wider.

Chemical resistance to water, acid, oil, UV, chlorine, etc… - Winner : Belt

Belt can be produce in different material (rubber, PU, …) which allows more possibilities than chains.