Fast assembly, as strong as a welded belt.

Since the first patent in 2014, we've been constantly improving ERO Joint® HP.

We've created new versions: with polyamide textile, with antistatic textile, with integrated drive guide, as well as a version for the food industry.

And we've also created tooling to facilitate assembly.

For this new version, we have once again optimized the axes, modified the shape of the assembly teeth, optimized the entire manufacturing process to gain in quality, created cable jumps to improve width cutting, and above all we are replacing the original cables with Zylon® (the polymer fiber with the highest tensile and bending strength).

Operating data

Manufacturing standard: Polyurethane 90 shore A light grey

Cables: A polymer cable wrapped around the pin in each tooth

Belts width : All widths from 6 to 1800mm

| Pitch | 8M | T10 | AT10 | H | 14M | T20 | AT20 | AT5 | T5 |

|---|---|---|---|---|---|---|---|---|---|

| Version | v1 | Zylon | Zylon | v1 | v1 | v1 | Zylon | v1 | v1 |

| Min. pulley Ø (mm) | 51 | 44 | 47 | 56 | 124 | 95 | 115 | 23 | 16 |

| Min. pulley Ø (tooth) | 120 | 80 | 120 | 79 | 200 | 120 | 180 | 60 | 30 |

| Permissible tension force ERO Joint HP (N/25mm) | 1871 | 1202 | 2213 | 970 | 1900 | 1900 | 3456 | 970 | 687 |

| Permissible tension force for aramid belts | 1313 | 798 | 1313 | 810 | 1136 | 1313 | 1313 | 908 | 687 |

| Permissible tension force steel belts | 1871 | 954 | 1871 | 970 | 2578 | 1871 | 2930 | 880 | 420 |

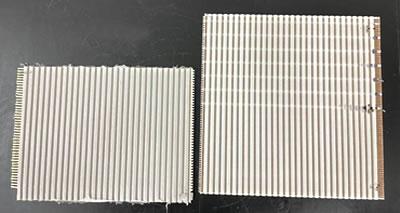

| Maximum plate width (except food) (mm) | 150 | 300 | 300 | 150 | 150 | 150 | 300 | 100 | 100 |

ERO Joint® HP Zylon® cable

Pitch available with Zylon cable: T10 - AT10 - AT10V - AT20

- Tensile modulus higher than Carbon and 3x higher than before

- 80% higher tensile strength than carbon and previous fiber

- No creep (previous fiber had 4x less creep than Kevlar)

- 30% more adhesion on our PU ERO Joint® HP

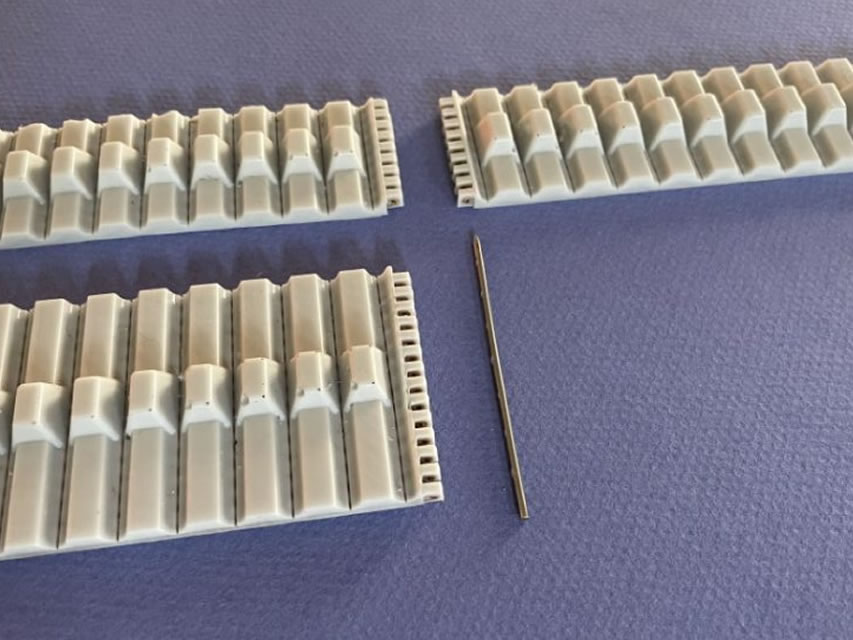

Teeth width:

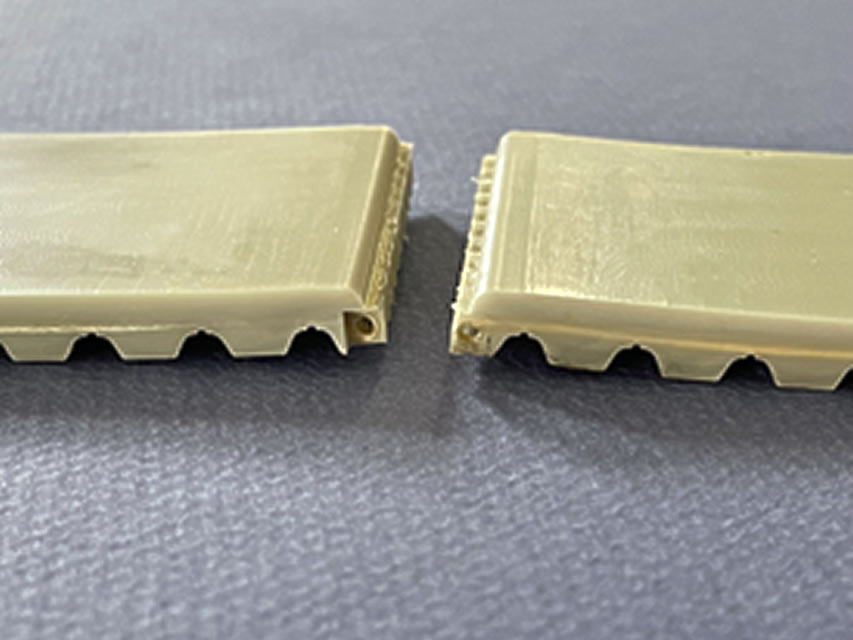

from 2,273mm to 1,785mm

| 1.785 | 2.273 | |

|---|---|---|

| 16 | 9 | 7 |

| 25 | 14 | 11 |

| 32 | 18 | 14 |

| 50 | 28 | 22 |

| 75 | 42 | 33 |

| 100 | 56 | 44 |

Zylon

old version VS new version

Pins:

from 2mm to 1.6mm

65mm long machined straight pins

(can be supplied in belt width)

Cutting lines:

16, 25, 32, 50, 100,..

Molds:

from 150 (or 200) to 300mm

New PU injection process → better quality

Benefits

ERO Joint HP® replaces any welded belt with ultra-fast installation.

The Zylon version is even more efficient, more stable under heavy loads and more durable.

ERO Joint® HP is a patented mechanical splicing solution for polyurethane belts. A hinge pin with a single stainless steel rod is used to close the belt.

ERO Joint® HP is produced in sheets from 100 to 300 mm wide, cut to size and welded to the base belt.

Belts are available with steel, aramid, HF or stainless steel Cords, with all types of coating, machining and guiding system.

The admissible tractive strain and service life are similar to those of welded belts.

We can supply finished belts, as well as plates that can be welded to polyurethane belts of any brand (with the same melting parameters as the belts).

Alternatives

Spiral joints

Mechanical spiral joints are as easy to assemble as an ERO Joint® HP joint, but their mechanical strength is very low.

Pin Joint

The Pin Joint mechanical jointing system is more difficult to assemble than an ERO Joint® HP joint.

Mechanical strength is also lower than an ERO Joint® HP joint.