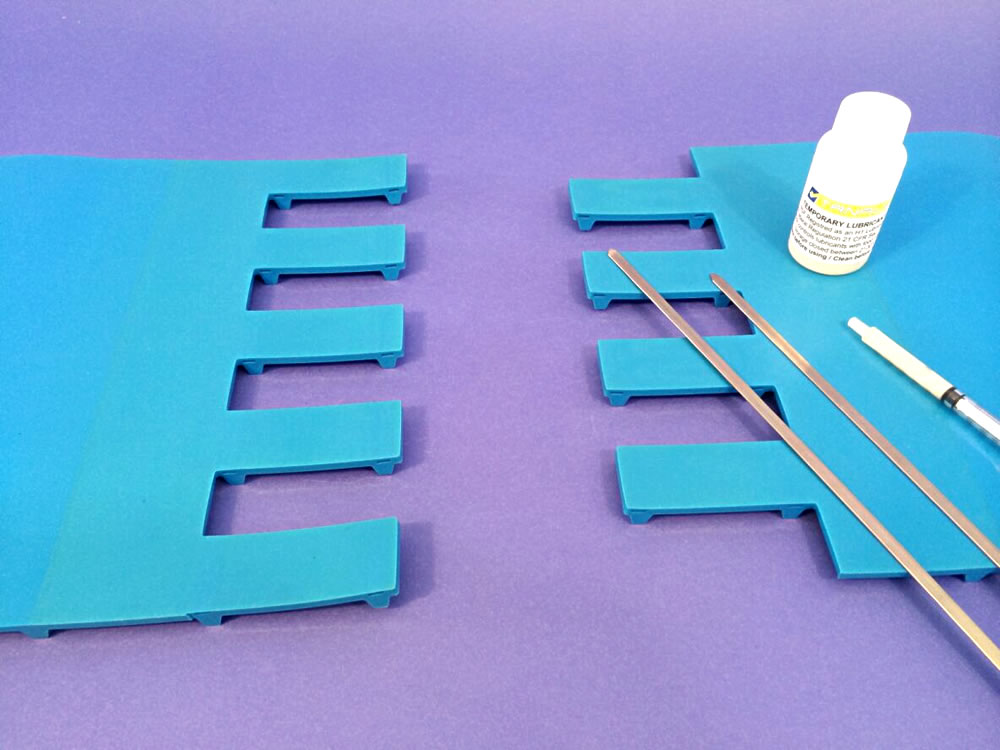

The mechanical fastening system ERO Joint® can be used in all types of conveyor belt over 1mm thick.

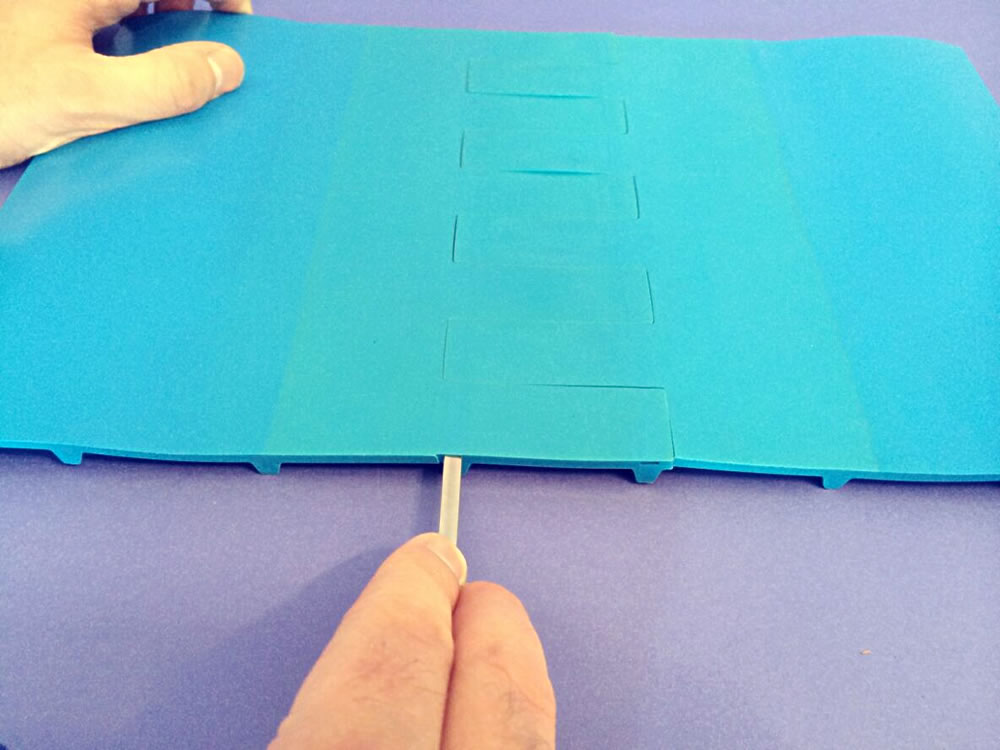

The assembly is made by threading of 3 transversal pins (stainless steel or polyacetal pins)

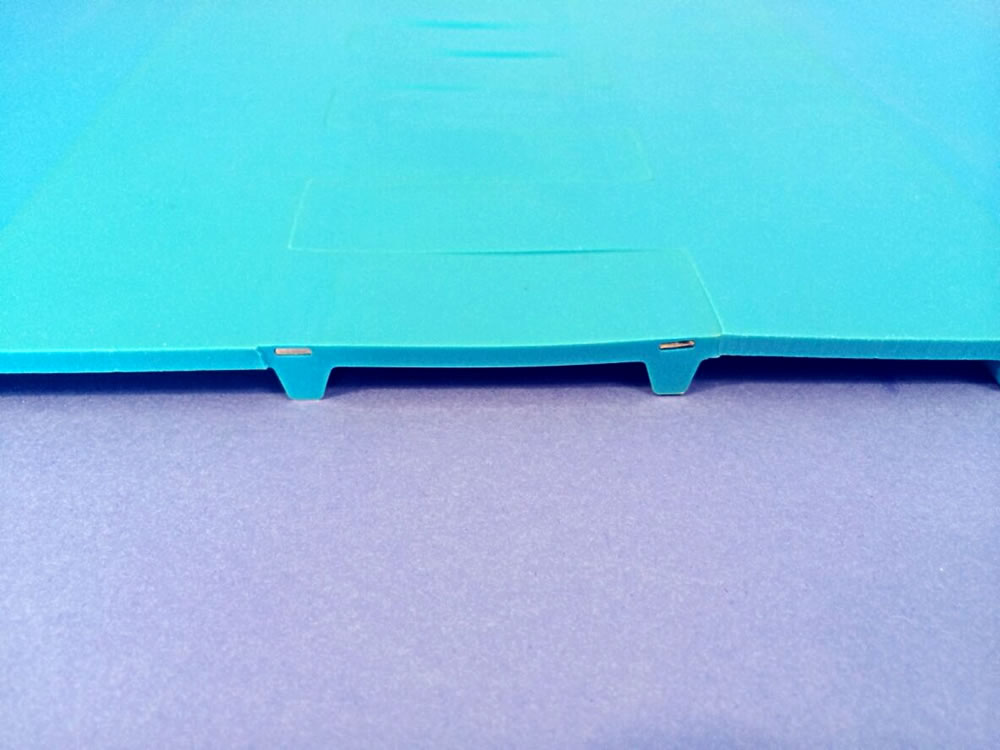

The ERO Joint® splice is integrated directly into the belt, without modifying the belt's upper structure, width or color.

Tensile Kevlar cord can be embedded in the Polyurethane on request.

Using ERO Joint® belts gives you complete freedom and flexibility: no special tools or welding procedures to comply with, no deburring and no risk to miss the welding. ERO Joint® conveyor belts are fast and easy to assemble.

Benefits

Quick and easy assembly.

With the ERO Joint® solution, you reduce intervention times and production downtime.

The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatiblewith conveyor belts scrapers.

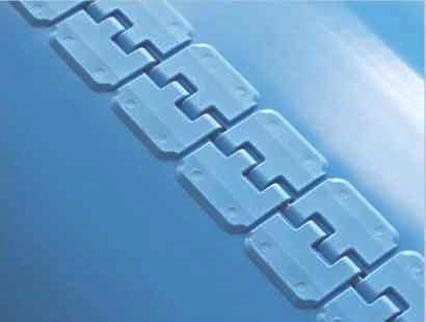

Mechanical fastening system ERO Joint® is a durable solution.

ERO joints can be modified (lengthened) to increase their mechanical strength.

ERO Joint® belts are manufactured in our workshops to the required length, using a patented process.

Alternatives

Fastening solution

A conveyor belt may be assembled with plastic hinge fasteners, but whatever the joining method used, conveyor belts with mechanical system ERO Joint® will have a longer lifespan.

The mechanical joint fastening systems ERO Joint® keep the thickness and the structure of belt on the top surface.

The ERO Joint® splicing system also reduces the risk of microbial contamination compared with other types of fastening.

PosiLace™ lacing solution

The ERO Joint® mechanical joining system does not alter the thickness and upper structure of the belt.

Compared with ERO Joint®, the PosiLace™ splice is not compatible with scrapers.

In addition, the ERO Joint® prevents the elongation effect at the splice.

On-site welding

Conveyor Belts can be welded on site by using a high-temperature press. However, this requires to buy a hot press or pay a maintenance intervention.

This type of operation takes at least 3 hours.

In contrast, ERO joint® mechanically assembled conveyor belts can be assembled in just 15 minutes. This system saves considerable maintenance time and reduces production costs.