Synchronous Timing belts BAT

The BAT timing belt tooth profile is based on the AT tooth profile, but the teeth are crowned. The belt is thus guided and self-centered, eliminating the need for flanges on pulleys and eliminating lateral belt drift. The belt's arched BAT profile reduces noise. BAT belt meshing is optimized.

Caution: it requires perfect pulley alignment and turns in one direction only. (For two-direction rotation, use BATK with drive guide).

| Advantages | Inconveniences |

|---|---|

| Self-steering: flangeless pulleys | Price |

| Very low noise level: less vibration when meshing | Works in one direction only (except BATK) |

| Very low polygonal effect | No quick-assembly system exists for this gearing |

| No vibration when using carrier or tension rollers on the tooth side (no minimum winding angle). |

Synchronous timing belts BATK

The BATK Synchronous timing belt is derived from the BAT timing belt. The Belt is self-guiding in both directions of travel with integrated guidance.

Recommended use:

- Special requirements for smooth running and transmission precision

- Limited installation dimensions

- Application in drive, linear and other technologies.

SFAT synchronous Timing belts

The tooth profile of SFAT timing belts is based on the AT profile, but the two toothings are offset by half a pitch in relation to each other. Combined with matching synchronous pulleys, the Belt is self-guiding. There's no need to use flanged Pulleys.

Recommended use:

- Running on flangeless synchronous Pulleys

- Increased requirements for smooth running (reduced polygonal effect)

Caution : Pulleys must be properly aligned, otherwise the teeth will be rapidly abraded in the center by the guide.

| Advantages | Inconveniences |

|---|---|

| Better meshing quality for longer service life | Does not accept large pulley misalignments (premature wear in the center) |

| Self-steering: flangeless pulleys | Price |

| Reduced noise level: the impact of meshing is limited, so the transmission is quieter. | No quick-assembly system exists for this gearing |

| Maximum transmissible power: the entire tooth width is used | |

| Reduced polygonal effect | |

| Reduced vibration: when using support rollers or rollers. |

Eagle herringbone synchronous Timing belts

A unique Timing belt concept. The unique H.O.T. (Helical Offset Tooth) herringbone toothed belt and pulley design enables extremely compact, quiet synchronous drive and high-precision synchronization. Thanks to this herringbone toothing, flanges are no longer required, making it particularly suitable for conveying applications, and reversing is possible without reservation. Eagle polyurethane timing belts are fitted as standard with steel cords and polyamide fabric on the teeth.

| Advantages | Inconveniences |

|---|---|

| Quieter operation than spur gears | Price |

| Self-guiding belt | Friction due to angled teeth. Both functions (guidance and transmission) are combined. |

| No flanges, so reduced width, total weight and inertia | Energy consumption |

| Low-backlash tooth profile - ideal for high-precision movements | Premature wear due to pulley misalignment |

| Reversible operation possible | No quick-assembly system exists for this gearing |

Timing belts GeQo Drive

GeQo Drive is an 8M belt with an STD tooth form optimized to reduce noise. The teeth are offset and the tooth profile slightly modified.

(GeQo Drive runs on STD8M pulleys with offset teeth).

The GeQo Drive is guided by the easy drive® system, which enables precise operation and accepts large pulley misalignments without the use of flanges.

GeQo Drive is much quieter and more precise than a conventional Belt.

Its alternating tooth profile enables it to operate tangentially, which is impossible for any other timing belt.

GeQo Drive combines the advantages of SFAT belts and easy drive® guidance to be as quiet as Eagle belts.

| Advantages | Inconveniences |

|---|---|

| Quieter operation than a spur gear. As quiet as an Eagle belt | |

| Self-guiding belt | |

| No flanges, so reduced width, total weight and inertia | |

| Low-backlash tooth profile - ideal for high-precision movements | |

| Reversible operation possible | |

| Energy consumption | |

| Accepts large pulley misalignments | |

| Can be used tangentially |

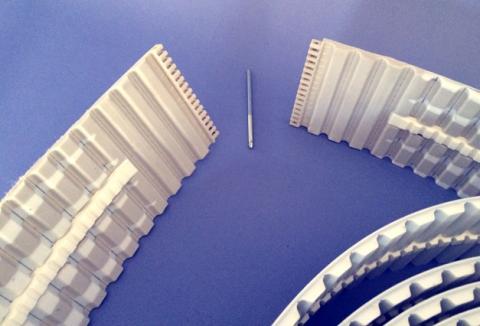

Synchronous timing belts with attached drive guide

Self-aligning drive guide belts are the result of combining standard belts with special polyurethane cranked trapezoidal drive guides. These guarantee extreme flexibility and allow the use of small-diameter pulleys.

The drive guide is fused onto the belt after milling a groove.

| Applications | Advantages | Inconveniences |

|---|---|---|

| Transport applications | Use with pulleys without flanges | |

| Handling applications | Insensitive to lateral pressure thanks to belt guidance | |

| Conveying applications | Reduces lateral belt movement | |

| Positioning applications | For all belt widths and timing belt pitches | |

| Available with ERO Joint® HP quick-connect system |

Synchronous Timing belts with coextruded drive guide

Timing belts with coextruded drive guides are a combination of synchronous belts and V-belts. The performance range corresponds to normal T or AT profiles, minus the width of the non-toothed belt. They outperform timing belts with drive guide inserts (better mechanical strength, more flexible in bending, more durable).

| Applications | Advantages | Inconveniences |

|---|---|---|

| Transport applications | Use without flanged pulley | |

| Handling applications | Insensitive to lateral pressure thanks to belt guidance (co-extruded guide belts withstand higher loads than other guidance systems) | |

| Conveying applications | Reduction of lateral belt movements | |

| Positioning applications | Accepts smaller winding diameters than timing belts with inserts | |

| Available with ERO Joint® HP quick-connect system |

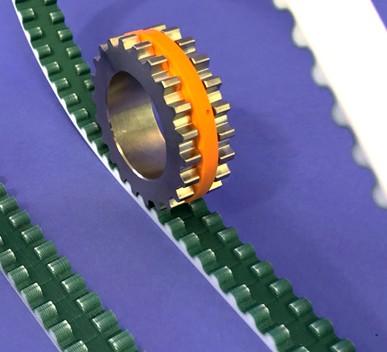

Synchronous timing belts with easy drive® guide rings

The Easy Drive® guide offers high directional stability for all tooth shapes, pitches and materials.

The Easy Drive® guide ring engages precisely with the Pulley.

The Belt no longer shifts, and guidance is perfect.

Pulley guide flanges:

Guide the belt over the pulley teeth.

The clearance between the Belt and the flanges is between 2 mm and 4 mm.

For standard belts, the inside width between flanges is toleranced in accordance with DIN ISO 2768-1 to allow for belt width tolerances and possible misalignments.

| Advantages | Inconveniences |

|---|---|

| For PU and neoprene belts | Available with ERO Joint® HP quick-connect system |

| Compatible with all tooth pitches and shapes | Guide profiles must be added under the belts |

| Pulley available in any material (steel, aluminium, cast iron or Delrin) | In the case of side loading and/or heavy loads, an integrated belt guide is imperative |

| Universal solution avoiding flanged pulleys | |

| Reduced vibrations | |

| Reduced pulley footprint | |

| Price comparable to timing belt solution with guide profile | |

| Available with ERO Joint® HP quick-connect system |