How to identify the problem with your V-belt?

Obvious warnings can include excessive drive noise, unusual vibrations and heat (overheated bearings). The first thing to check is to listen to and handle the Belt. A belt that squeals or whistles, rubs, squeaks... is a sign of trouble. A hot belt is another warning sign.

Further analysis to check the Belt is necessary. Check for exceptional wear points. Check for abnormal belt wear (back wear, sidewall wear, cracked base, hardened outside of belt...). Investigate whether the problem is related to other transmission components: bent or damaged shafts, damaged casing.

Premature Belt failure

Broken Belt

- Insufficient transmission capacity

- Belt forced onto driving belt

- Foreign object in transmission

- Severe shock

- Recalculate according to Gates Determination Manual (E1/20070)

- Use retrofit device during assembly

- Protect transmission with appropriate housing

- Allow for shocks in the calculation

Belt(s) not transmitting load (slipping); no apparent reason

- Insufficient transmission capacity

- Damaged traction cords

- Damaged pulley grooves

- Variation in center distance

- Recalculate load (slippage) according to the Gates Determination Manual (E1/20070)

- Install correctly

- Assess wear and replace defective components

- Check if center distance changes during operation.

Damaged belt flanks

- Pulley misalignment

- Damaged pull cords

- Check and correct alignment

- Follow assembly procedure

Belt layer separation

- Pulleys too small

- Outer roller too small

- Check transmission calculation and replace with larger Pulleys

- Increase outer roller diameter

Abnormal belt wear

Back wear

- Friction against housing

- Roller malfunction

- Replace or repair housing

- Replace roller

Upper sidewall wear

- Incorrect belt/pulley combination (belt too small for groove)

- Use the right Belt/Pulley combination

Sidewall wear

- Skating

- Misalignment

- Pulley wear

- Unsuitable Belt

- Retension until skidding stops

- Align pulleys

- Replace pulleys

- Use correctly sized Belt

Base wear

- Belt hits bottom of groove

- Worn pulleys

- Foreign object in pulleys

- Use correct Belt/Pulley combination

- Replace pulleys

- Clean pulleys

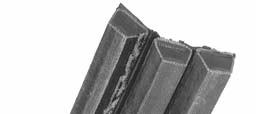

Cracked base

- Pulley diameter insufficient

- Slippage

- Outer roller too small

- Inappropriate storage

- Use larger-diameter pulleys

- Tension until slippage stops

- Increase outer roller diameter

- Do not wind, bend or twist the Belt

- Avoid heat and sunlight

Burnt or hardened base or sides

- Skating

- Pulley wear

- Insufficient transmission capacity

- Variation in center distance

- Tension until slippage stops

- Replace pulleys

- Recalculate according to Gates Determination Manual (E1/20070)

- Check if center distance changes during operation

Unusual noise and vibrations

Screeching or hissing

- Skating

- Foreign object in transmission

- Retighten transmission

- Clean Belt and Pulleys

Beat

- Insufficient tension

- Belts of different origin

- Misalignment

- Retighten transmission

- Replace with matched set of belts

- Align pulleys to distribute tension evenly across all belts

Friction

- Contact with housing

- Repair, replace or design a new housing

Squeaking

- Damaged bearings

- Replace, align and lubricate bearings

Excessively noisy transmission

- Unsuitable Belt

- Worn pulleys

- Foreign object in transmission

- Use the correct Belt size. Use the correct tooth profile for Synchronous belts

- Replace pulleys

- Clean pulleys and fit a cover. Remove rust, paint or dirt from grooves

Jumping Belts

- Insufficient tension

- Belts of different origin

- Pulley misalignment

- Retighten transmission

- Replace with matched set of Belts

- Align pulleys

Excessive transmission vibration

- Unsuitable Belt

- Poor design

- Eccentric pulley

- Play on transmission components

- Use correctly sized Belt

- Check transmission structure and strength of bearings and supports

- Replace pulley

- Check stability, load-bearing capacity, installation and maintenance of transmission components (casings, motor mountings, motor mounts, hubs, shafts, bearings, etc.)

Multiple transmission problems

Separation of the bonding band

- Pulley wear

- Incorrect distance between grooves

- Replacing pulleys

- Use standard multiple pulleys

Frayed, worn or damaged backing strip

- Contact with housing

- Outer roller defective or damaged

- Check housing

- Repair or replace outer roller

Powerband® jumps out of transmission

- Foreign object in transmission

- Clean pulleys. Use single belts to avoid dirt accumulation in the grooves

One or more strands emerge from the pulleys

- Misalignment

- Insufficient tension

- Aligning the transmission

- Retension transmission